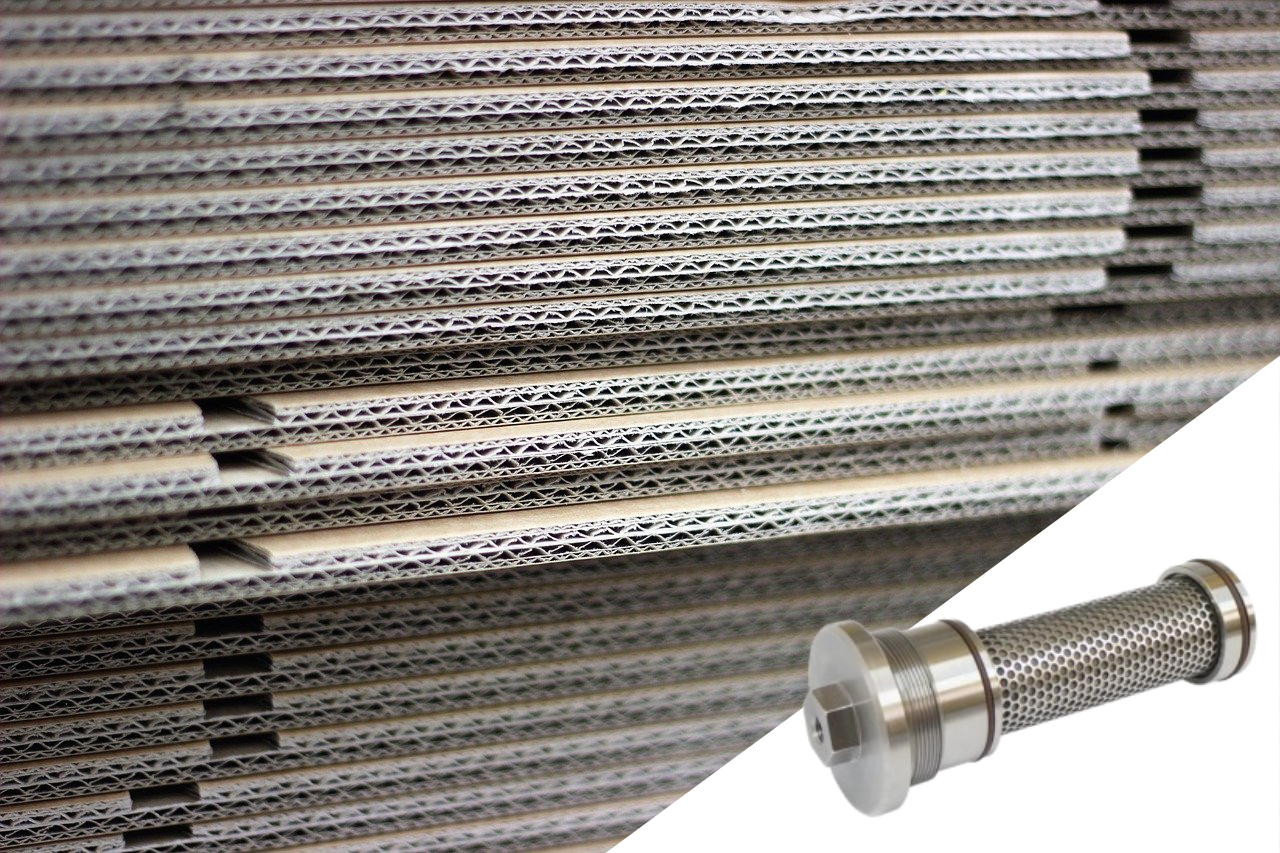

In the past, many engineers chose not to change in-line filters, and it is understandable why. Changing an in-line filter used to be a very complicated and tricky process. Requiring three hands, the process was time-consuming and expensive. Plus, the rubbish used to be on the outside of the filter, and when changed, this would get dislodged into the glueing system and block the nozzles. New advances in in-line filters mean that this is no longer the case; there is now no excuse not to change your in-line filter!

Why You Should Change Your In-Line Filter

You need to change your in-line filter every 3 months for a multitude of reasons. If you don’t change your in-line filter regularly, then it will get blocked, and that blockage will reduce adhesive volume. That’s a lot of lost money in wasted product, all because of a tiny thing like the in-line filter.

Back in the day, changing an in-line filter did come with a risk of sending all the accumulated rubbish into the nozzles, which then meant having to spend time unblocking that nozzle. These days, however, filters are much better and are designed to contain all the rubbish inside of the cartridge, where it can be safely trapped and held in place for when you want to take that filter out – nothing can be dislodged and end up in the nozzles, so you’ll never have to worry about that kind of blockage again.

Changing the in-line filter of an adhesive melt system is quite literally a 30-second job and only needs one person to do it. Getting into the habit of changing it means it won’t seem any more of a chore than all your other day-to-day workfloor tasks.

What If I Don’t Change The In-Line Filter?

Wave goodbye to a tidy sum! It might not seem a lot for one day’s worth of production but every little adds up…

How To Change Your In-Line Filter

Turn off the air supply to your tank, relieve the pressure by opening your drain valve and then take out the old filter and disregard. You can then fit the new in-line filter. Allow the filter housing to reach temperature and tighten the filter. It’s as simple as that.

If you need advice about in-line filters, The Adhesive Laundry can help. We are experts in solving degraded adhesive issues and have a range of products and equipment available. You can send us your old filters for cleaning and return, which will cost far less than buying brand-new filters. For more information, contact us today.

Image source: Pixabay