Hot melt gluing systems are crucial in the packaging, labelling, and converting industries, delivering a rapid, measured quantity of adhesive for many different applications.

For high levels of productivity, it’s vital that this equipment operates efficiently, as any delays in dispensing adhesive can slow down the production line, while blockages caused by degraded adhesive cause lengthy downtime while remedial action is taken.

Knowing how your hot melt system operates, and the different components involved, can be invaluable in helping you to address operational issues – with many components able to be cleaned, instead of replaced, to remove adhesive blockages. It also enables you to carry out preventive maintenance, keeping components clean, to avert more disruptive repairs later.

The Components In A Hot Melt Gluing System

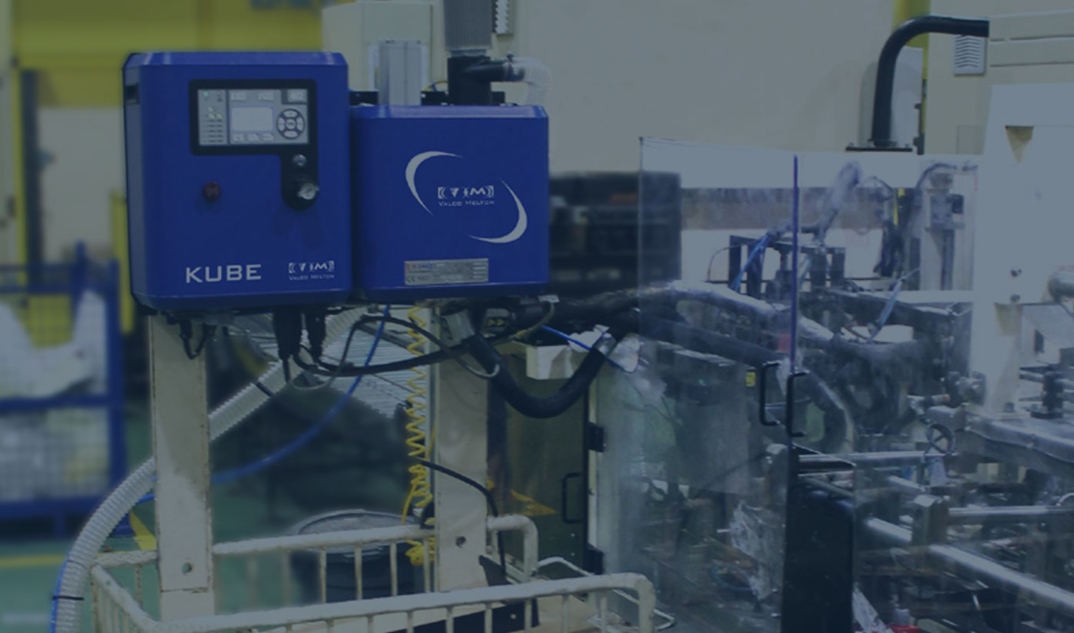

A hot melt system comprises several key parts:

The glue tank melts the solid adhesive to a liquid and pumps it via the tank filter into the Manifold. This is connected to the glue hoses, which in turn connect to the glue guns. Each gun has a module and nozzle for distribution of the adhesive. A single tank can provide capacity for up to six hoses. Usually, hoses are configured in pairs, fours, or sixes.

The tank also has a feed which, in some systems, may be automatic.

Filters play an important role as these prevent contamination or debris from entering the system and affecting the quality of the glue delivery. There is a filter between the tank and the hoses (the tank filter), and another between the hose and the glue guns (the in-line filter).

A solenoid valve is mounted on the top of the glue guns which activates the modules on the gun.

Contact Adhesive Laundry For A Superior Cleaning Solution!

Replacing components, including filters, from your hot melt gluing system is a costly and often unnecessary mistake. At Adhesive Laundry, we’re experts in cleaning HMS equipment, to ensure that it operates efficiently, without irritating blockages and breakdowns slowing down your production line.

With over three decades of experience, our specialists really do understand the practicalities of running hot melt equipment and have the technical knowledge to solve any problem. Our unique tank and nozzle cleaning service is the perfect antidote to adhesive blockages – a far cheaper and quicker way to return your hot melt system equipment to optimum condition! For more information, why not get in touch on 01480 869220 or click here to request a call back.