How To Replace Your Hot Melt Filter Without Ruining The System

Periodic replacement of the filter in your hot melt system is essential to ensure it delivers a reliable service. Without timely replacement, the system will start to operate inefficiently, affecting productivity and driving up running costs, as degraded material accumulates in the manifold.

The Problem Of DIY Filter Replacement In Hot Melt System

It can be tempting to try to save money by undertaking hot melt filter replacement yourself. After all, you can remove the system from service at a time that suits production, carry out the repair without incurring labour costs, and be ready to resume the production line as soon as the filter is changed.

However, a DIY filter replacement can pose significant risks. When the tank filter is replaced, particles of degraded material can become dislodged, and may, later, cause blockages in components, such as the pump, nozzles, or guns.

If this occurs, the hot melt system will cease to function effectively, requiring it to be shut down while the cause of the problem is traced and rectified. This will affect productivity, increase costs, and potentially mean that other system parts require premature replacement.

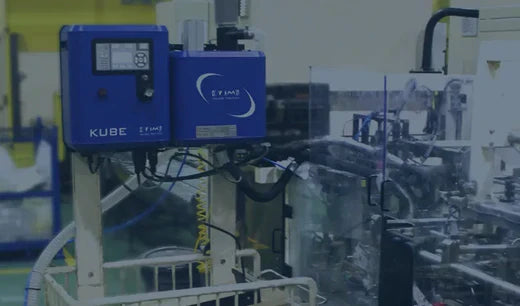

How We Carry Out Expert Hot Melt Filter Replacement

While you can change your hot melt system’s filter yourself in principle, it makes economic and time-saving sense to arrange for an expert from The Adhesive Laundry to carry out a trustworthy, professional replacement instead.

Not only does this save you precious time, keeping your equipment downtime to an absolute minimum, but your hot melt system is also guaranteed a thorough clean to ensure that no degraded material is left in hidden corners that could cause problems later.

When we replace the filter in a hot melt system, we complete the following steps:

- Firstly, the unit is broken down to its individual components.

- The pump is cleaned, and new seals are fitted.

- The manifold is removed from the tank and given a thorough clean.

- The tank filter is replaced, and the tank is cleaned.

- All electronics are tested to ensure their safety.

- Covers are cleaned and, if necessary, repaired.

- The base is cleaned and resprayed.

- A new pressure relief valve is fitted.

- Finally, the tank is reinsulated.

We recognise that productivity is important to your business so, while your hot melt system is out of action, we can supply a loan unit to help minimise disruption to your production line.

Contact Us

At The Adhesive Laundry, as well as tank filter replacements, we offer a full cleaning and rebuilding service for pumps, nozzles, modules, and guns, ensuring that your hot melt system remains in prime condition, offering reliable service for the long-term. Please call or email us today to find out more.